ADHESIVE SOLUTIONS

ITI Supplies – News

116-> Strong Bonding and easy to relocate/remove

Secure identification in industrial environments requires a strong adhesive. However, some applications also require easy removal or relocation of labels (a common challenge with strong bonding). Our tags with partial high tech adhesive combine a strong bond and yet easy removal. Combo tag 9660 and label 468 also ensures that no adhesive remains on the product.

Secure identification in industrial environments requires a strong adhesive. However, some applications also require easy removal or relocation of labels (a common challenge with strong bonding). Our tags with partial high tech adhesive combine a strong bond and yet easy removal. Combo tag 9660 and label 468 also ensures that no adhesive remains on the product.

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

115-> Strong Adhesive vs. Conventional Tagging

There are a lot of ways fastening/securing tags to products in factory and warehouse environments (protective wallets, adhesive tapes, glue sticks, etc.). Our multi-functional tag/label is equipped with high tech adhesives that stick to virtually any surface and leave no residue during and after removal. These tear resistant tags/labels are printed using thermal transfer or laser printers and can be attached using the adhesive patch or our various secure attachment clips. Application: Multiple usage matching plant and warehouse diversity.

There are a lot of ways fastening/securing tags to products in factory and warehouse environments (protective wallets, adhesive tapes, glue sticks, etc.). Our multi-functional tag/label is equipped with high tech adhesives that stick to virtually any surface and leave no residue during and after removal. These tear resistant tags/labels are printed using thermal transfer or laser printers and can be attached using the adhesive patch or our various secure attachment clips. Application: Multiple usage matching plant and warehouse diversity.

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

114-> Residue-free removal of adhesive labels

Users of labels with strong adhesion know it well – labels with a strong tack can leave adhesive or other unwanted residue when being removed from the finished product. Recently developed adhesive technology allows for high tack/strong bond that stays 100% with the labeling material, not on the surface. Additionally, when applied to a thicker and less flexible tag material, our new non-residue adhesives can even further improve easy removal of the tag/label. This means that the whole processing chain will be completely free from adhesive residue, from the printer to automatic processing, applying the label, and the end product that you produce. The result: Adhesive applications that work and, satisfied users and customers!

Users of labels with strong adhesion know it well – labels with a strong tack can leave adhesive or other unwanted residue when being removed from the finished product. Recently developed adhesive technology allows for high tack/strong bond that stays 100% with the labeling material, not on the surface. Additionally, when applied to a thicker and less flexible tag material, our new non-residue adhesives can even further improve easy removal of the tag/label. This means that the whole processing chain will be completely free from adhesive residue, from the printer to automatic processing, applying the label, and the end product that you produce. The result: Adhesive applications that work and, satisfied users and customers!

Application: Strong tack without leaving adhesive residue

Benefit: Fewer malfunctions, less cleaning required for printers and residue-free finished products

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

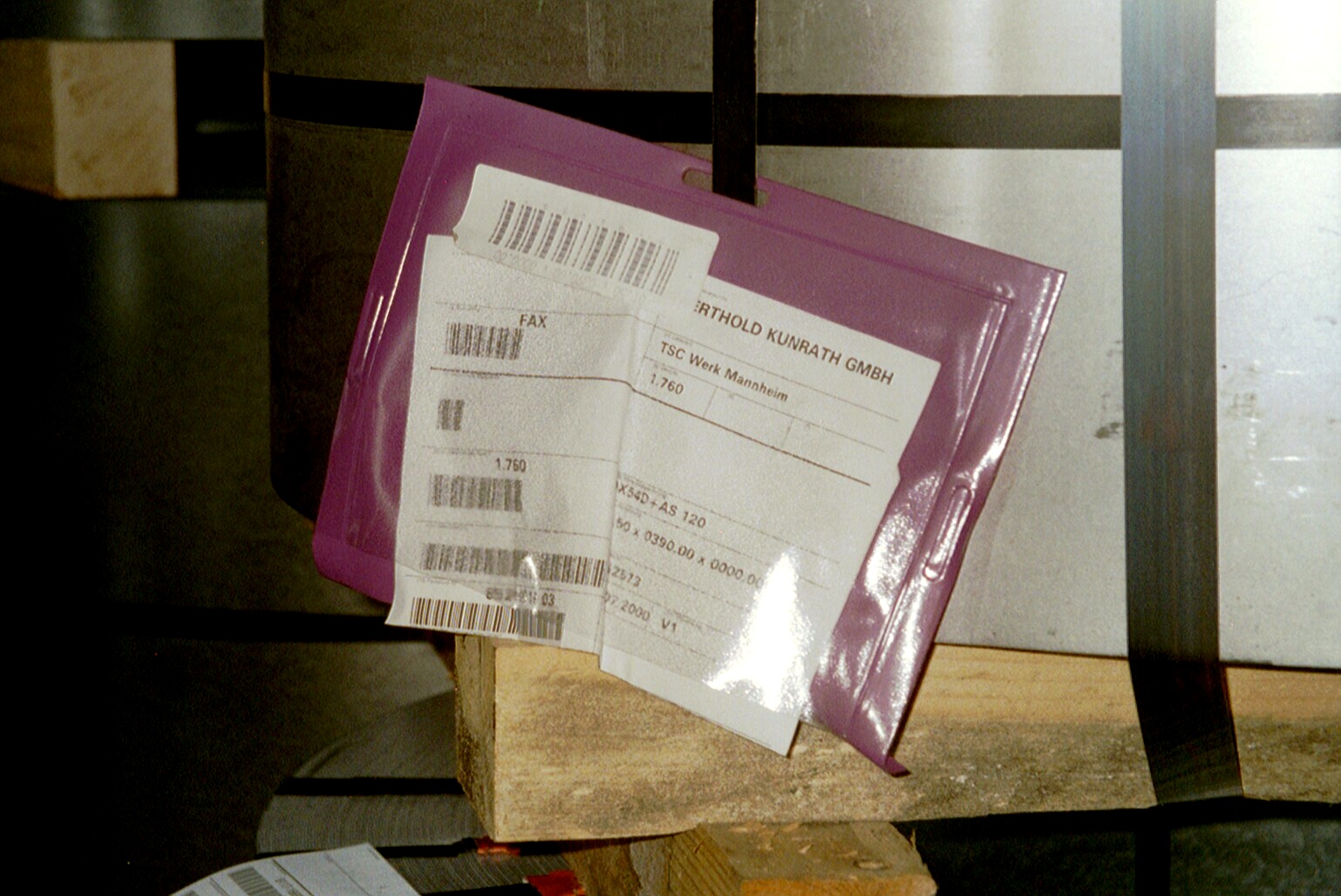

113-> Laser Tags Replace Plastic Wallets

Application: AIAG/Odette solution without plastic wallets

Benefit: Elimination of wallets and standardized identification

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

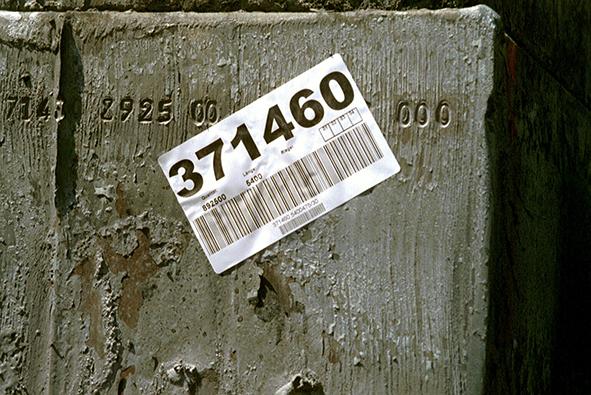

112-> Stock organization with 2 part tags with adhesive backo

Stock organization means registering all material movements. For a Dutch specialist in processing hot-rolled strip the following question arose: "How can I satisfy my customers with an AIAG/Odette solution and simultaneously improve my stock organization?" The answer is easy, with a two-part tag. Matching the minimum height of the products, the height of one section of the tag is 4 cm. That is sufficient space for the internal data and grants reliable access to the data on the side of the packages. The combination tag, an AIAG/Odette customer tag scaled down to A6 size with a tear-off section, printed on a thermal transfer printer, excels by its perfect printout and functionality. An adhesive strip on the tag for fastening to the steel strapping avoids glue residue on the steel plates, is easy to handle and sticks extremely well. Satisfied customers and improved stocktaking - the advantages are obvious. It will be a pleasure to send you samples.

Stock organization means registering all material movements. For a Dutch specialist in processing hot-rolled strip the following question arose: "How can I satisfy my customers with an AIAG/Odette solution and simultaneously improve my stock organization?" The answer is easy, with a two-part tag. Matching the minimum height of the products, the height of one section of the tag is 4 cm. That is sufficient space for the internal data and grants reliable access to the data on the side of the packages. The combination tag, an AIAG/Odette customer tag scaled down to A6 size with a tear-off section, printed on a thermal transfer printer, excels by its perfect printout and functionality. An adhesive strip on the tag for fastening to the steel strapping avoids glue residue on the steel plates, is easy to handle and sticks extremely well. Satisfied customers and improved stocktaking - the advantages are obvious. It will be a pleasure to send you samples.

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

111-> Secure labeling in icy temperatures

Work processes do not take a winter break. This also applies to identifying incoming goods. In Steel Service Centers this means labels must stick to cold, wet and frosted products. The process must continue even if temperatures are extremely low. Standard labels do not adhere below 5°C/40°F; you must acclimatize the goods before applying the label. This is not required with the newly developed PA-75-202 adhesive. GRAPHIPLAST® labels can now be used at temperatures down to -60°F/-50°C.

Work processes do not take a winter break. This also applies to identifying incoming goods. In Steel Service Centers this means labels must stick to cold, wet and frosted products. The process must continue even if temperatures are extremely low. Standard labels do not adhere below 5°C/40°F; you must acclimatize the goods before applying the label. This is not required with the newly developed PA-75-202 adhesive. GRAPHIPLAST® labels can now be used at temperatures down to -60°F/-50°C.

Application: Secure labeling, even in winter.

Benefit: Quick and secure labeling at low temperatures.

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

110-> Adhesion to sensitive stainless steel surfaces

The manufacturing of specialty stainless steel is time-consuming and expensive. To ensure a smooth material flow, self-adhesive labels are used for this process. They control the packaging process as well as warehouse and shipping logistics. Mirror surfaces are a particular challenge for labeling. Labels must provide a secure bond and at the same time be removable. But it doesn’t end here – the area where the adhesive was applied to the surface must not be visible – not even as a label “shadow”. Labels made from GRAPHIPLAST® 7177 with a adhesive leave no

trace – guaranteed – for a mirror finish on fridges and sinks.

The manufacturing of specialty stainless steel is time-consuming and expensive. To ensure a smooth material flow, self-adhesive labels are used for this process. They control the packaging process as well as warehouse and shipping logistics. Mirror surfaces are a particular challenge for labeling. Labels must provide a secure bond and at the same time be removable. But it doesn’t end here – the area where the adhesive was applied to the surface must not be visible – not even as a label “shadow”. Labels made from GRAPHIPLAST® 7177 with a adhesive leave no

trace – guaranteed – for a mirror finish on fridges and sinks.

Application: 100% removable adhesion to stainless steel

Benefit: An all-round talent for material flow control

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

109-> Tire logistics in rely on GRAPHIPLAST

Branded tires from different manufacturers are distributed by a leading logistics company. Warehouse organisation and picking items for deliveries require a barcode label with a good adhesion to rubber. GRAPHIPLAST® 7177, in combination with a special adhesive, provides optimum adhesion to tires. The data is printed on the label by thermal transfer printers. As the labels are only used for a short period of time, the excellent price/performance ratio of the solution made the difference.

Branded tires from different manufacturers are distributed by a leading logistics company. Warehouse organisation and picking items for deliveries require a barcode label with a good adhesion to rubber. GRAPHIPLAST® 7177, in combination with a special adhesive, provides optimum adhesion to tires. The data is printed on the label by thermal transfer printers. As the labels are only used for a short period of time, the excellent price/performance ratio of the solution made the difference.

Application: Perfect adhesion to rubber

Benefit: An all-round talent for material flow control

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

108-> Adhesive labels for frozen surfaces and extreme humidity

We have always made efforts to widen the bandwidth of product properties. For the identification with self-adhesive labels this means to be able to ensure a good bond in different climatic conditions and to achieve good adhesion to a wide range of surfaces. Moisture, dust and oil represent barriers for adhesives – they prevent the adhesive from developing a permanent bond with the actual medium. The new PK-80-651 and PK-50-701 GRAPHIPLAST® adhesives combine many of these properties in one product and help to create adhesive labels for a wide range of applications. They can be used, e.g. for sticking to surfaces affected by moisture and hoar frost.

We have always made efforts to widen the bandwidth of product properties. For the identification with self-adhesive labels this means to be able to ensure a good bond in different climatic conditions and to achieve good adhesion to a wide range of surfaces. Moisture, dust and oil represent barriers for adhesives – they prevent the adhesive from developing a permanent bond with the actual medium. The new PK-80-651 and PK-50-701 GRAPHIPLAST® adhesives combine many of these properties in one product and help to create adhesive labels for a wide range of applications. They can be used, e.g. for sticking to surfaces affected by moisture and hoar frost.

Application: Adhesion in freezing and high moisture conditions

Benefit: Secure identification with universal adhesives

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

107-> User-friendly container identification

We have always made efforts to widen the bandwidth of product properties. For the identification with self-adhesive labels this means to be able to ensure a good bond in different climatic conditions and to achieve good adhesion to a wide range of surfaces. Moisture, dust and oil represent barriers for adhesives – they prevent the adhesive from developing a permanent bond with the actual medium. The new PK-80-651 and PK-50-701 GRAPHIPLAST® adhesives combine many of these properties in one product and help to create adhesive labels for a wide range of applications. They can be used, e.g. for sticking to surfaces affected by moisture and hoar frost.

We have always made efforts to widen the bandwidth of product properties. For the identification with self-adhesive labels this means to be able to ensure a good bond in different climatic conditions and to achieve good adhesion to a wide range of surfaces. Moisture, dust and oil represent barriers for adhesives – they prevent the adhesive from developing a permanent bond with the actual medium. The new PK-80-651 and PK-50-701 GRAPHIPLAST® adhesives combine many of these properties in one product and help to create adhesive labels for a wide range of applications. They can be used, e.g. for sticking to surfaces affected by moisture and hoar frost.

Application: functional solution for container identification

Benefit: An all-round talent for material flow control

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

106-> Partial application of adhesive offers more options

The identification of stacked sheet metal or sheet metal coils with sensitive surfaces requires labels with a firm bond. These labels enable good fixing to the strap. It is important that the part of the label that sticks over the edge of the strap is free from glue, to avoid any transfer of adhesive onto the surface. Partial application of adhesive is an established technology, which, until now, could only be used in a limited way for high-strength, permanent adhesives. Our PK-80-601 adhesive has both extremely high bond strength and it can be applied partially. An ideal solution for applications where the glue has to be applied precisely to a specific, small area and where high adhesive strength has to be combined with adhesive application in selected areas.

The identification of stacked sheet metal or sheet metal coils with sensitive surfaces requires labels with a firm bond. These labels enable good fixing to the strap. It is important that the part of the label that sticks over the edge of the strap is free from glue, to avoid any transfer of adhesive onto the surface. Partial application of adhesive is an established technology, which, until now, could only be used in a limited way for high-strength, permanent adhesives. Our PK-80-601 adhesive has both extremely high bond strength and it can be applied partially. An ideal solution for applications where the glue has to be applied precisely to a specific, small area and where high adhesive strength has to be combined with adhesive application in selected areas.

Application: Strap identification without wallet, adh. AIAG tags

Benefit: An all-round talent for material flow control

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

105-> Better bond for self-adhesive labels with roller

Attaching an adhesive label is an important process, the main factor for bonding strength. Even application and contact pressure determine the adhesive strength that is actually achieved. To achieve a permanent bond, the use of a simple roller, similar to the ones used for wallpapering, is recommended. This simple device also prevents the contamination of labels, for instance by dirty gloves. You can find this solution in any DIY store or request rollers from us. Because sticking to difficult products requires great care.

Attaching an adhesive label is an important process, the main factor for bonding strength. Even application and contact pressure determine the adhesive strength that is actually achieved. To achieve a permanent bond, the use of a simple roller, similar to the ones used for wallpapering, is recommended. This simple device also prevents the contamination of labels, for instance by dirty gloves. You can find this solution in any DIY store or request rollers from us. Because sticking to difficult products requires great care.

Application: Optimum adhesion for self-adhesive labels

Benefit: Good adhesion on difficult surfaces!

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

104-> The Combi Label/Tag - A New Option

The combination of robust plastic films and adhesives with a strong glue offers benefits, e.g. in steel service centers, as it allows to attach the label/tag sticking and hanging. Up to now, the use of thick adhesive layers to achieve adequate adhesion to various steel surfaces had been its limitation, due to the residue these left in the printing systems. The combination of #7177 in 150 µ with PK-80-601 adhesive creates a combination label that achieves top performance in both applications tag or self-adhesive label. At the same time, adhesive breakout inside the printer is reduced to a minimum, due to the adhesive’s compact nature. In the true sense of the word - a neat solution.

The combination of robust plastic films and adhesives with a strong glue offers benefits, e.g. in steel service centers, as it allows to attach the label/tag sticking and hanging. Up to now, the use of thick adhesive layers to achieve adequate adhesion to various steel surfaces had been its limitation, due to the residue these left in the printing systems. The combination of #7177 in 150 µ with PK-80-601 adhesive creates a combination label that achieves top performance in both applications tag or self-adhesive label. At the same time, adhesive breakout inside the printer is reduced to a minimum, due to the adhesive’s compact nature. In the true sense of the word - a neat solution.

Application: Tag or self-adh. label - optimum results for both.

Benefit: Good adhesion on difficult surfaces!

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

103-> Adhesive Labels for 450° C (850F)

The general shortage of raw materials has led to an increase in exports of semi-finished goods. In the metal industry, the identification of billets is usually carried out by marking the piece number with a stamp or via color coding (tube markers). However, this is not sufficient for the consignees’ identification requirements, as the information is poorly legible due to soiling and the impact of weather. Customers are looking for information that is easy to read for example #7940 labels - suitable for temperatures up to 350° C. The strong aluminium foil can be easily applied with gloves. Special rollers enable the attaching of the label without smearing the surface and/or the barcode. The special adhesive guarantees a secure adhesion to scaly and rough surfaces. A proven solution that works.

The general shortage of raw materials has led to an increase in exports of semi-finished goods. In the metal industry, the identification of billets is usually carried out by marking the piece number with a stamp or via color coding (tube markers). However, this is not sufficient for the consignees’ identification requirements, as the information is poorly legible due to soiling and the impact of weather. Customers are looking for information that is easy to read for example #7940 labels - suitable for temperatures up to 350° C. The strong aluminium foil can be easily applied with gloves. Special rollers enable the attaching of the label without smearing the surface and/or the barcode. The special adhesive guarantees a secure adhesion to scaly and rough surfaces. A proven solution that works.

Application: Attaching labels to hot billets

Benefit: Low-price and effective fastening

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

102-> New solution for AIAG ID GRAPHIPLAST® 7527

How goods for inventory will be received in the future can be observed already at some automotive manufacturers in Europe and the US. Unloading containers from pallets by robots followed by checking of shape and identification with data plausibility checks. With this method of receiving inventory, conventional paper labels cause problems. Especially if corners stick out or residue of old labels cannot be removed. Our new development, GRAPHIPLAST® 7527 will solve this problem. The unique adhesive and the special layout of the AIAG form create flexibility for different types of containers. Secure labeling and simple removal without residue guarantee satisfied customers.

How goods for inventory will be received in the future can be observed already at some automotive manufacturers in Europe and the US. Unloading containers from pallets by robots followed by checking of shape and identification with data plausibility checks. With this method of receiving inventory, conventional paper labels cause problems. Especially if corners stick out or residue of old labels cannot be removed. Our new development, GRAPHIPLAST® 7527 will solve this problem. The unique adhesive and the special layout of the AIAG form create flexibility for different types of containers. Secure labeling and simple removal without residue guarantee satisfied customers.

Application: An all-round solution for container identification.

Benefit: Satisfied customers with an economical solution

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669

101-> Adhesive solution for rough surfaces

Heat, cold, scale, saw residue and saw emulsion are just some of the challenges requiring thick layers of ultrastrong adhesive. The new PA-80-601 adhesive can be applied as an adhesive field in selected areas of the label/tag, enabling a much higher quantity of adhesive to be applied. No more additional glue has to be applied by hand from a bucket.

Heat, cold, scale, saw residue and saw emulsion are just some of the challenges requiring thick layers of ultrastrong adhesive. The new PA-80-601 adhesive can be applied as an adhesive field in selected areas of the label/tag, enabling a much higher quantity of adhesive to be applied. No more additional glue has to be applied by hand from a bucket.

Application: Sticking of labels on very difficult surfaces

Benefit: Savings. It can also be used as both a label and a hangtag

with attachment hole where needed.

Sample Requests: info@itiproductosindustriales.com or call +1 305-393-8669